| Additional Support | |

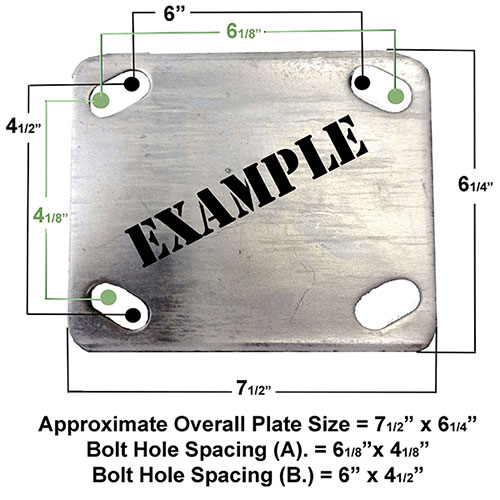

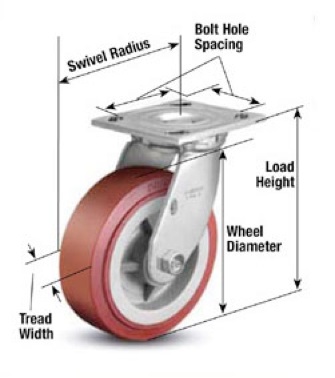

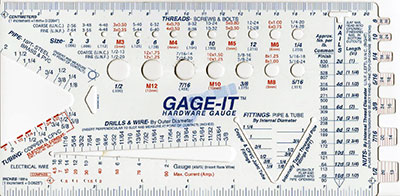

| Taking Measurements Measuring the Mounting Plate:  To measure the top / mounting plate first measure the outside or the overall length and width of the plate. Then measure the bolt hole spacing, from the inside or outside of each bolt hole to the next, as pictured here... Measuring the Caster And Wheel:  Mounting Height: Measure from the bottom of the wheel to top of the mounting point. Swivel Radius: Measure the center of the mounting point, (axis), to the outer most point of the wheel. Tread Width: Measure the overall width of the of the wheel. Wheel Diameter: Measure the overall height of the wheel from top to bottom. Measuring Stem Style Casters: Gauge: There are several style of stems.  The easiest way to measure these is by using a “Hardware Gauge” (pictured below). You can buy one at any hardware or home store for about $2. Simply insert the stem into the drill bit holes and match it up to the size listed, ie: 7/16” The easiest way to measure these is by using a “Hardware Gauge” (pictured below). You can buy one at any hardware or home store for about $2. Simply insert the stem into the drill bit holes and match it up to the size listed, ie: 7/16” (should be a snug fit). Wrench: You can also use a standard set of wrenches, for instance take a 7/16”. Use  the open end of the wrench and put the open end of the wrench and put it on the stem, it should be a snug fit. Always measure the thickest area. Adjustable Wrench: Tighten the adjustable wrench around the widest part of the stem. Then take a ruler and measure the distance of the wrench opening. This Gauge are not actual size... Measure Length: Use a ruler to measure from the top of the stem to the base plate. Overall length of stem. |

|

| Caster & Wheel Terminology | |

Axle: Bolt that attaches wheel into caster yoke (frame, bracket). Bearing Cap: Part used with single precision bearing wheels; integrates a spanner thrust bushing with bearing guard, only covers the bearing and not the full wheel hub. 2 per wheel. Bearings: Wheel bearings provide either mechanical rolling assistance or a slick surface that reduces friction and increases roll-ability. Raceway bearings are a device on a swivel caster, enabling it to turn while bearing the load. Blank Wheel: Wheel without bearing installed (plain bore). Bolt Hole Pattern: Measurement between mounting holes on top plate, including length and width dimensions. Bore: Refers to inner dimension of blank wheel or bearing. Brake: Component part of caster, when activated, assists in stopping wheel from rolling. Caster: Complete assembly of caster yoke (frame), wheel(s), & axle; enabling equipment to roll. Caster Pad: Assembly that is either welded or bolted to the bottom of a piece of equipment that enables a caster with a top plate to be quickly installed or removed. May also refer to a weld plate that has an identical overall size and bolt pattern to casters to reinforce mounting area. Centered Hub: Wheel hub that has the same dimensions on either side; typically used in casters. Hub usually protrudes from wheel core. Chemical Bond: Method of bonding wheel tread to wheel core using glue or a chemical reaction that fuses the materials together. Cold Forged: A chemical procedure softening steel for forming. Heat treat is usually followed after cold forge to re-enhance the steel strength. Complete Wheel: A wheel that has bearings installed. Crown Tread: Wheel face that is slightly rounded; reduces surface area & friction. Crown tread helps wheel roll & turn easier. Cut & Welded Design: Describes casters made using a raceway & legs that are formed separately & welded together instead of stamping one piece. Double Ball Raceway: 2 sets of bearings rolling in tracks held together with a kingpin; one set supports the load, while the other assists in swivel thrust. Drop Forged / Hot Forged: A procedure that billet is heated to burning red before being stamped to certain shapes that otherwise could have been done by welding. The process increases the density of metal & further enhances its strength by eliminating any inconsistency of welding. Most of our heavy duty casters are made with top plate, raceway and king bolts forged to one piece. Durometer: System of establishing the hardness of rubber, plastic or polyurethane using an “A” scale or "D" scale when it is beyond "A" scale's range. Dust Cap: Metal cap that helps keep foreign materials out of raceways. Dynamic Load: Maximum load of a caster/wheel while rolling. Fastening Type: Refers to the way a caster is attached to a piece of equipment. (i.e.: top plate, stem, hollow kingpin, and etc). Floor Lock: Accessory used in conjunction with casters; a devise to secure carts from moving on level floors. High-Temp: Casters or wheels (including all parts), that are capable of operating at higher temperatures without failure or deformation. Hollow Kingpin Caster: Tubular rivet used to hold swivel raceways together; the hole in the rivet kingpin can accept a bolt or customized modular stems for any particular mounting requirement. Hub Length: Distance from one side of wheel hub to the other. Inner Diameter "I.D.": Measurement of wheel bore, bearing bore or tubing inside diameter. Integrally Forged: Different components are made into one single component through hot forging process. The process increases the density of metal and further enhances its strength by eliminating the problem of one or more components failure at severe application. Keyway: Machined notch inside the wheel bore allowing wheel to be locked onto a drive shaft using the “key” that slides into correlating notches between the wheel bore and drive shaft, shaft is then able to turn the wheel. Wheels with thick metal hubs can be machined with keyways. Kingpin: Bolt or rivet used to hold swivel raceways together; some of our heavier duty drop forged casters have the kingpin integrally forged as one piece with the top plate. Kingpins are typically the weakest point of a caster; Kingpinless casters are stronger. Kingpinless: Casters without a bolt & nut kingpin. A Kingpinless caster’s top plate and inner raceway are a one piece construction or integrally forged; the outer raceway with legs attached are held together with the inner raceway by hardened steel ball bearings. This design offers unsurpassed durability and use in abusive and demanding shock load applications that may cause kingpin casters to fail. Load Capacity: Maximum weight carried by a single caster or wheel under ideal operating conditions. Overloading could result in catastrophic failure. Mechanical Bond: Method of bonding wheel tread to the wheel core by means of inter-locking materials together. Modular Stem Casters: Casters created to accept a variety of customized fastening requirements. Mounting Bolt / Attaching Bolt: Fastening bolt or screw to attach casters to equipment. Offset Hub: Wheel hub that protrudes on one side and is recessed on the other; Offset hubs are popular on wheels used on hand trucks and other mobile equipment using wheels instead of casters. "O.D.": Measurement of the outside diameter of a wheel, bearing, tube, socket, etc. Plain Bore: Wheel bore that rides directly on axle, no bearing. Raceway: Section of a swivel caster or wheel bearing; bearings that roll in an embossed or machined track. Retainer Washer: Washer to keep bearings & grease in & debris out. Rivet Axle: Permanent axle type used mostly on light duty casters. Rivet Kingpin: Kingpin that has the both ends enlarged by hydraulic spin or staking, to hold a swivel raceway together. Seals: Select swivel raceways & wheels may have seals installed to keep debris out and keep grease in. Some wheel bearings are sealed and don’t require maintenance. Check temperature ranges & limitations. Shock Load: Impact or vibration sustained by caster/wheel from loading or outside forces, such as weight dropped on equipment, equipment running into obstacles. Side Thrust: Horizontal force from non-rolling direction of a caster. Stamped Yoke: Main portion of caster frame assembly made from a single stamped piece of steel instead of multiple parts welded together. Static Load: Maximum load of a caster/wheel while stationary. Thread Guards: Metal or plastic disks that cover wheel hub preventing debris from getting into bearings or wrapping around axle. Thrust Washer: Washers used between wheel hub and caster leg. Wheel: Wheel only, not in a caster frame. Yoke: Swivel or rigid frame of a caster. Also referred to as Fork or Rig. Zerk: Grease fitting on wheels, caster raceways or axles. |

|

| Choosing A Caster | |

| Choosing a Caster Factors to Consider ... Load Capacity: The first questions usually asked pertains to what the total weight to be moved is (includes the weight of the cart or equipment & the load it will be carrying) and on how many casters. The simple formula is; divide the total load weight by the number of casters or wheels you will use; that will tell you the load capacity you will need for each caster or wheel. Total load ÷ Number of Casters or Wheels on Cart = Minimum load Capacity Per Caster or Wheel Be aware that the best combination of wheel, bearings, and caster frame requires more knowledge than just the load capacity rating. Our load capacity ratings are based on a speed of up to 2.5 mph intermittent usage over smooth floors in ideal operating conditions. Your application is seldom ideal. Did you know that heat generated from a heavy load being moved at a higher speed can cause the bonding agent which holds the tire on the wheel center to break down? The result can be tire separation and wheel failure. Floor Protection: In order to determine the proper wheel for your application, you need to consider the type and condition of the floors they will be rolling on. Wheels with soft non-marking rubber treads (tires) provide the best floor protection on hardwood floors, such as in your home or in a school gymnasium. Wheels with Polyurethane treads provide floor protection when soft rubber wheels lack the needed capacity. There are also countless applications where only a hard non- metal or metal wheel will do the job. Remember that repetitive travel over the same path with wheels having a hard surface will eventually wear the surface of even concrete floors. Each of our wheels have numerous applications for which they are best suited. Operating Conditions: Other factors to consider when selecting a caster or wheel are: is abuse, impact or shock loads likely; is noise a factor; what speed will it be rolling; will the equipment be moved manually or by mechanically powered equipment; will they be used in temperature extremes hot/cold; will they come in contact with water, chemicals, oil/grease; will they be rolling over debris, cords, floor joints, etc; what is the condition and types of the floor surfaces (smooth, rough, uneven, broken concrete, coated concrete, asphalt, gravel, grass, carpet, hard- wood, linoleum, tile, etc). Each wheel type can be used in many different applications, and there are countless applications. We urge you to read the pages describing each of our wheels and casters. If you still have questions or wish to confirm your choice, please Contact our Sales Department. Extreme Climate: We offer a broad selection of wheels capable of withstanding a wide range of temperatures from -50° F, to 1,300° F. Please be aware that standard bearing grease will begin to harden at 20° F preventing bearings from optimum functionality. Both high temperature and low temperature grease is available, please inquire. Cost Efficiency Analysis: Initial cost is an important factor in a purchase decision; however the fact is that choosing the least expensive casters that meet your requirements can save money up front; but may actually cost you more in the long term; including the cost for maintenance, down time, and replacement. Selecting stronger casters with a higher weight capacity, larger wheels, and better bearings insures maximum productivity and longer caster life. |

|

| How do I contact you? | |

| Please click here for our company contact information. | |